Have you ever wondered what happens to all those plastic bottles, containers, and packaging we throw away every day? Most of it ends up in landfills, burned, or worse, floating in our oceans.

But what if I told you that the very plastic trash we toss could be turned into something useful – like furniture, tools, art, or even houses?

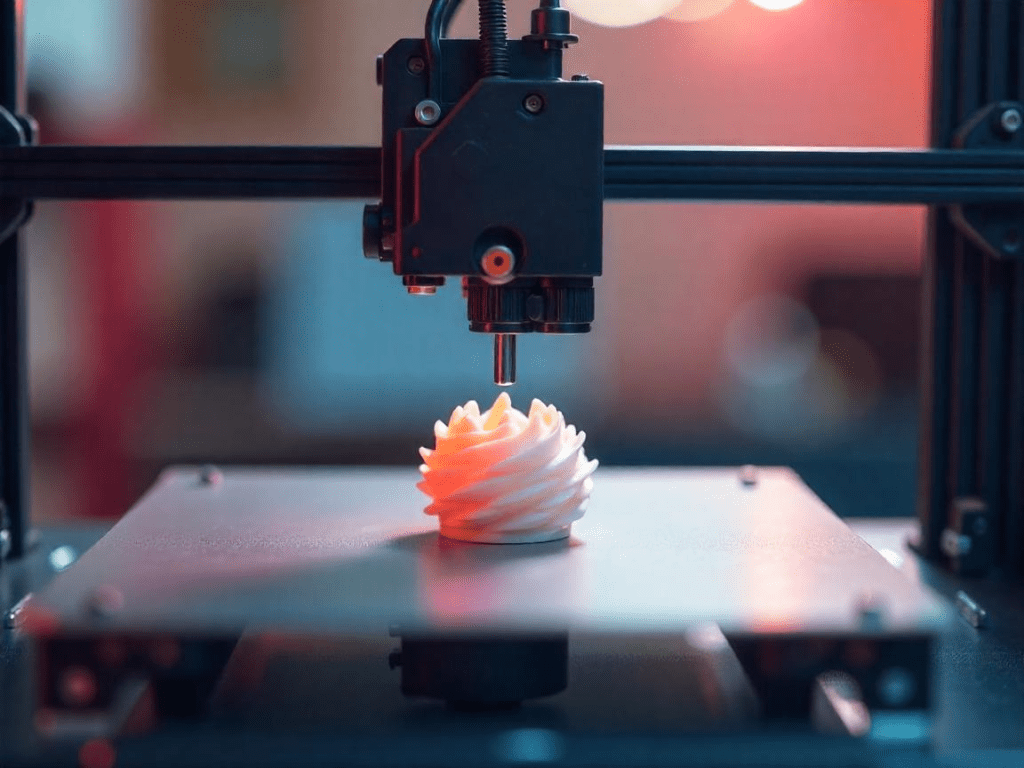

That’s 3D printing with recycled plastic waste.

This isn’t just some niche tech experiment. It’s a real, growing solution that combines two powerful forces: recycling plastic waste and 3D printing.

In this article, we’re going to dive deep into what this means, how it works, why it matters, and how it could change the world as we know it.

What is 3D Printing with Recycled Plastic Waste?

3D printing (also called additive manufacturing) is a way to make three-dimensional objects layer by layer from a digital file.

It’s like printing a regular document, but instead of ink, you use material like plastic, and instead of a flat page, you get a full object.

Now, imagine using recycled plastic — like old water bottles, packaging, or broken containers — as the raw material for that printing.

Instead of tossing plastic in the bin or shipping it off to a recycling plant, we can clean it, shred it, and turn it into filament or pellets that feed into a 3D printer.

Boom! Trash becomes treasure.

This process is part of a bigger movement to close the loop on plastic waste and promote the circular economy — where materials are reused and repurposed rather than thrown away.

The Problem: Plastic Waste is Everywhere

Let’s talk facts. According to the UN Environment Programme, the world produces about 430 million tons of plastic every year, and only 9% of it gets recycled properly.

The rest just piles up in landfills, clogs rivers, ends up in the stomachs of marine animals, or gets burned, releasing toxic fumes. It takes hundreds of years to decompose, and in the meantime, it breaks into microplastics that end up in our food and even in our bodies.

We have a plastic waste crisis on our hands. And traditional recycling isn’t keeping up.

That’s where 3D printing comes in. It offers a more direct, local, and creative way to reuse plastic waste.

How 3D Printing Helps Solve the Plastic Problem

So how does this technology help?

1. Local Recycling Made Easy:

Instead of sending plastic to big recycling plants, we can process it locally.

Communities, schools, or individuals can collect, sort, clean, and process plastic right at home or in small workshops.

2. Less Waste, More Value:

Instead of downcycling plastic into low-quality material, 3D printing can upcycle it into useful, high-quality objects like:

- Phone stands

- Planters

- Chairs

- Prosthetics

- Toys

- Tools

3. Lower Carbon Footprint:

Since everything is produced locally and on-demand, we cut down the need for long supply chains, packaging, and excess inventory.

This means fewer emissions.

4. Custom, Creative, and Functional:

Need a part for your broken appliance? Want a custom lamp holder? With 3D printing and recycled plastic, you can design and create it yourself.

How Plastic Waste Becomes 3D Printing Material

Okay, let’s get into the nitty-gritty.

Here’s how your average soda bottle becomes something 3D printed:

1. Collection:

Plastic waste is collected from homes, beaches, schools, or businesses. Most common types used are:

- PET (polyethylene terephthalate) — from bottles

- HDPE (high-density polyethylene) — from containers

- PLA (polylactic acid) — from biodegradable plastics

2. Sorting and Cleaning:

Plastics are separated by type and cleaned thoroughly to remove dirt, labels, or other residues.

3. Shredding:

Once clean, the plastic is shredded into small pieces using a plastic shredder. These chips are the base material.

4. Melting and Extruding:

The chips are then melted and pushed through an extruder, which forms thin strands called filaments. These filaments are what 3D printers use.

Alternatively, some printers use pellet-based systems that can print directly from shredded plastic, skipping filament production.

Projects like Precious Plastic have made open-source machines that anyone can use to do all this from a small workshop.

What Can Be Made with Recycled Plastic and a 3D Printer?

Honestly? A lot more than you think.

Here are some amazing things people are already 3D printing with recycled plastic:

1. Furniture and Home Items:

Chairs, tables, lamps, shelves can all be made from recycled waste plastic. Companies like Print Your City are building entire urban furniture sets using local plastic waste.

2. Fashion Accessories:

Think sunglasses, jewelry, belts, and even shoes. These items turn plastic trash into wearable statements.

3. Educational Tools and Toys:

Schools are using this method to teach kids about sustainability while printing fun toys or learning aids from collected plastic waste.

4. Medical Devices:

In developing regions, prosthetic limbs and medical tools are being printed from recycled materials, offering life-changing help at a lower cost.

5. Construction:

Yes, there are even startups creating building blocks and bricks from plastic waste for low-cost housing.

Real-World Projects and Success Stories

Let’s look at some inspiring examples of how recycled plastic and 3D printing are changing lives and landscapes:

1. The New Raw – Print Your City

In cities like Thessaloniki, Greece, the “Print Your City” initiative by The New Raw allows locals to bring their plastic waste and turn it into public furniture like benches, bike racks, and planters.

It’s art meets action.

2. Reflow

Reflow turns plastic waste into high-quality 3D printing filament and works with global communities to create jobs and reduce landfill plastic.

3. Plasticpreneur

Plasticpreneur provides small-scale machines for local entrepreneurs to turn plastic waste into products like phone cases, bowls, or tools, all 3D printed.

4. Million Waves Project

This U.S.-based initiative takes ocean plastic and uses it to 3D print prosthetic limbs for people in need, especially in underserved communities.

These projects prove one thing: that we can take plastic pollution and turn it into opportunity.

Environmental Benefits and Real Impact

So how much of a difference does this really make?

Let’s break down the key environmental benefits:

1. Less Plastic in Landfills and Oceans:

Every bottle or container reused is one less piece of plastic polluting our environment. When scaled, this can dramatically reduce waste.

2. Lower Emissions:

Making new plastic from petroleum is energy-intensive. Recycling and reusing plastic locally means lower carbon emissions across the board.

3. Supports Circular Economy:

Instead of a one-time use, plastics become part of a continuous cycle of use, recovery, and reuse. That’s the whole idea behind a circular economy — keep materials in use, not in waste bins.

4. Empowers Local Communities:

People can create value from their own trash. That creates local jobs, reduces dependency on imported goods, and makes recycling feel personal and impactful.

How You Can Get Started

You don’t need a high-tech lab to start playing your part in this movement.

1. Join a Local Initiative:

Look for local makerspaces, schools, or NGOs running 3D printing or plastic recycling programs. They often welcome volunteers, donations, and ideas.

2. Start Small at Home:

You can begin by:

- Sorting and collecting your own plastic waste

- Learning about plastic types (PET, HDPE, PLA)

- Using DIY open-source machines from Precious Plastic

- Buying or building a low-cost shredder and extruder

3. Educate and Advocate:

Talk to your school, workplace, or local government about starting a plastic-to-printing program. Awareness is the first step to action.

4. Support Ethical Brands:

Many startups now sell 3D-printed goods made from recycled plastic. By supporting them, you’re fueling demand for sustainable products.

Final Thoughts

We’re drowning in plastic waste, and traditional recycling just isn’t cutting it. But we now have the tools to turn that trash into treasure, locally, creatively, and sustainably.

3D printing with recycled plastic waste isn’t just an innovation but also a solution. One that empowers people, protects the environment, and transforms how we think about waste.

It’s a revolution in how we create, consume, and conserve. The next time you hold a plastic bottle, imagine what it could become. Then go out and make it happen.